Do you need more info?

Contact us and ask for a trial

Sign in and register your data to get urgently contacted form our sales to answer your questions.

Our tube drilling machine type FORUS with electronic controls and brushless motors is a versatile and easy to use solution. It is featured by electronic adjustments and enables to make perpendicular and angle drilling on tubes, rectangular or square profiles, flat plates in different sections and made of steel, stainless steel, aluminum, brass and titanium. It is a modular drilling machine that can be supplied with single or double drilling head.

Drilling head is extremely sturdy made and feed is provided from a recirculating ball screw powered through a brushless motor. Rotating table on which drilling heads are mounted can turn +/- 40°÷90° in order to achieve perfectly perpendicular as well as angle holes.

This unit is suitable also for tube “flowdrill” and for tapping on round tubes or square profiles. Tube feed can be manual or fully automatic.

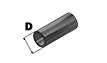

300-1500 Rpm

300-1500 Rpm  D = 5-50 mm

D = 5-50 mm  M1= 2,2 kw

M1= 2,2 kw  M2= 2,2 Nm

M2= 2,2 Nm  40-90 degrees

40-90 degrees  D = 10-114 mm (4,5" max)

D = 10-114 mm (4,5" max)  L = 80x80 mm

L = 80x80 mm  490 kg

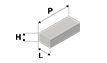

490 kg  H = 170 cmP = 150 cmL = 170 cm

H = 170 cmP = 150 cmL = 170 cm Sign in and register your data to get urgently contacted form our sales to answer your questions.

Garboli put at disposal his skilled personnel to support you with technical advices,assistance and information about products and services.