Do you need more info?

Contact us and ask for a trial

Sign in and register your data to get urgently contacted form our sales to answer your questions.

Engineered for edge deburring, satin finish and surface finishing on square and rectangular tubing, our wet operated flat grinding machine type GPS-Modulo also enables to process metal sheets and plates made of stainless steel, iron, aluminum, brass , as well as other metals. This unit is particularly suitable for plasma cut metal sheet or sheared metal plates deburring.

This flat grinding machine is available in different configurations and enables to use abrasive belts, brushes for satin finish process and orbital brushes for deburring. Our sheet metal finishing machine can work either with two or three interchangeable heads. Surface finishing can be either “wet” or “dry”, by connecting specific dust collection hoods to the machine. Several special equipment are also available on request.

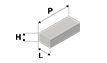

L = 10/300 mmH = 1/150 mmP = min.140 mm

L = 10/300 mmH = 1/150 mmP = min.140 mm

1-10 m/min

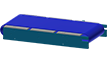

1-10 m/min  1900 kg

1900 kg  H = 202 cmP = 140 cmL = 200 cm

H = 202 cmP = 140 cmL = 200 cm

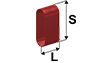

S = 2000 mm

L = 300 mm

10-20 m/s

D = 250 mm

1400 Rpm (With inverter 720-1500 Rpm)

D = 350 mm

V = 800 Rpm

Sign in and register your data to get urgently contacted form our sales to answer your questions.

Garboli put at disposal his skilled personnel to support you with technical advices,assistance and information about products and services.