Products

- Home

- Products

LPC 90-135

Orbital belt grinding machine

D = 5-25/5-35 mm(1" max)

D = 5-25/5-35 mm(1" max)  R1 min. 46/48 mmR2 = 1,5 x Ø mm

R1 min. 46/48 mmR2 = 1,5 x Ø mm

LPC 160

Orbital polishing machine

D = 5-50 mm(2" max)

D = 5-50 mm(2" max)  R1 min. 80 mmR2 = 1,5 x Ø mm

R1 min. 80 mmR2 = 1,5 x Ø mm

LPC 160 Wet

Orbital belt grinding machine

D = 5-50 mm(2" max)

D = 5-50 mm(2" max)  R1 min. 80 mmR2 = 1,5 x Ø mm

R1 min. 80 mmR2 = 1,5 x Ø mm

LPC 160 Mirror

Orbital belt buffing machine

D = 5-50 mm(2" max)

D = 5-50 mm(2" max)  R1 min. 80 mmR2 = 1,5 x Ø mm

R1 min. 80 mmR2 = 1,5 x Ø mm

LPC 160 Vs

Planetary belt polishing machine

R = 1,2 x Ø mm

R = 1,2 x Ø mm  D = 5-50 mm(2" max)

D = 5-50 mm(2" max)

LPC 160 S

Double head polishing unit

D = 5-50 mm(2" max)

D = 5-50 mm(2" max)  S = 622 mmL = 30 mm

S = 622 mmL = 30 mm

LPC 300

Orbital abrasive belts polishing machine

D = 5-114 mm(4,5" max)

D = 5-114 mm(4,5" max)  R1 = min. 150 mmR2 = 1,5 x Ø mm

R1 = min. 150 mmR2 = 1,5 x Ø mm

LPC 300 Wet

Abrasive belt grinding machine

D = 5-114 mm(4,5" max)

D = 5-114 mm(4,5" max)  R1 = min. 150 mmR2 = 1,5 x Ø mm

R1 = min. 150 mmR2 = 1,5 x Ø mm

LPC 300 Mirror

Orbital polisher

D = 5-114 mm(4,5" max)

D = 5-114 mm(4,5" max)  R1 = min. 150 mmR2 = 1,5 x Ø mm

R1 = min. 150 mmR2 = 1,5 x Ø mm

LPC 300 Vs

Planetary abrasive belts polishing machine

R = 1,2 x Ø mm

R = 1,2 x Ø mm  D = 5-114 mm(4,5" max)

D = 5-114 mm(4,5" max)

LPC 300 S

Double head polishing machine

D = 5-114 mm(4,5" max)

D = 5-114 mm(4,5" max)  S = 940 mmL = 60 mm

S = 940 mmL = 60 mm

LPC 500

Orbital pipe polisher with abrasive belts

D = 10-203 mm(8" max)

D = 10-203 mm(8" max)  R min. = 225 mm

R min. = 225 mm

LPC 500 Wet

Orbital abrasive belts finishing machine

D = 10-203 mm(8" max)

D = 10-203 mm(8" max)  R min. = 225 mm

R min. = 225 mm

LPC 500 Mirror

Orbital polishing machine

D = 10-203 mm(8" max)

D = 10-203 mm(8" max)  R min. = 225 mm

R min. = 225 mm

LPC 500 TE

Planetary tube grinding machine

R = 1,2 x Ø mm

R = 1,2 x Ø mm  D = 10-203 mm(8" max)

D = 10-203 mm(8" max)

LPC 500 S

Double head orbital belts grinding machine

D = 10-203 mm(8" max)

D = 10-203 mm(8" max)  S = 1500 mmL = 90 mm

S = 1500 mmL = 90 mm

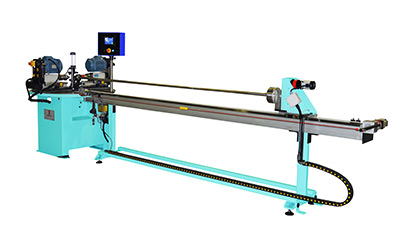

LT 130

Abrasive belts orbital grinding machine

D = 10-127 mm(5" max)

D = 10-127 mm(5" max)  S = 2000 mmL = 120 mm

S = 2000 mmL = 120 mm

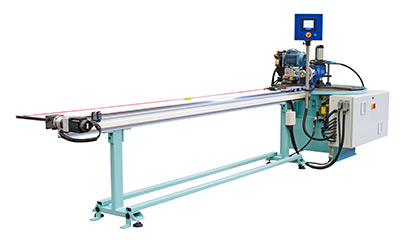

LT 130 WET

Orbital abrasive belt polishing machine

D = 10-127 mm(5" max)

D = 10-127 mm(5" max)  S = 2000 mmL = 120 mm

S = 2000 mmL = 120 mm

LT 130 Mirror

Mirror polishing machine for straight tubes

D = 10-127 mm(5" max)

D = 10-127 mm(5" max)  S = 2000 mmL = 120 mm

S = 2000 mmL = 120 mm

LT 130 S

Orbital grinding line with planetary polishing system

D = 10-127 mm(5" max)

D = 10-127 mm(5" max)  S = 2000 mmL = 120 mm

S = 2000 mmL = 120 mm

LT 130 WIRE

Planetary grinding machine - special version

D = 2-50 mm(2" max)

D = 2-50 mm(2" max)  S = 2000 mmL = 120 mm

S = 2000 mmL = 120 mm

LT 200

Abrasive belts grinding machine

D = 20-219 mm(8,6" max)

D = 20-219 mm(8,6" max)  S = 2000 mmL = 120 mm

S = 2000 mmL = 120 mm

LT 200 WET

Orbital abrasive belt polishing machine

D = 20-219 mm(8,6" max)

D = 20-219 mm(8,6" max)  S = 2000 mmL = 120 mm

S = 2000 mmL = 120 mm

LT 200 Mirror

Planetary tube buffing machine

D = 20-219 mm(8,6" max)

D = 20-219 mm(8,6" max)  S = 2000 mmL = 120 mm

S = 2000 mmL = 120 mm

LT 200 S

Orbital grinding line

D = 20-219 mm(8,6" max)

D = 20-219 mm(8,6" max)  S = 2000 mmL = 120 mm

S = 2000 mmL = 120 mm

LT TITAN

Planetary grinding machine for wire, bars and tubes with abrasive belts orbital system

D = 1-120 mm(5" max)

D = 1-120 mm(5" max)  S = 2050 mmL = 150 mm

S = 2050 mmL = 150 mm .jpg)

GPS Modulo

Wet operated flat grinding machine

L = 10/300 mmH = 1/150 mmP = min.140 mm

L = 10/300 mmH = 1/150 mmP = min.140 mm

GPS Belt

Drum belt grinder

L = 10-300 mmH = 1-150 mmP = min.140 mm

L = 10-300 mmH = 1-150 mmP = min.140 mm  S = 2000 mmL = 300 mm

S = 2000 mmL = 300 mm

GPS Brush

Metal sheet brushing machine

L = 10-300 mmH = 1-150 mmP = min.140 mm

L = 10-300 mmH = 1-150 mmP = min.140 mm  D = 250 mm

D = 250 mm

FORUS EASY

Electromechanic tube drilling machine

300-1500 Rpm

300-1500 Rpm  D = 5-50 mm

D = 5-50 mm

DUO

Multitask grinding machine

D = 10-80 mm (3" max)L = 20-3000 mm

D = 10-80 mm (3" max)L = 20-3000 mm  L = 10-150 mmH = 1-100 mmP = min.160 mm

L = 10-150 mmH = 1-100 mmP = min.160 mm

TRIS

Abrasive belt centerless polishing machine

D = 10-80 mm(3" max)

D = 10-80 mm(3" max)  S = 2180 mmL = 140 mm

S = 2180 mmL = 140 mm

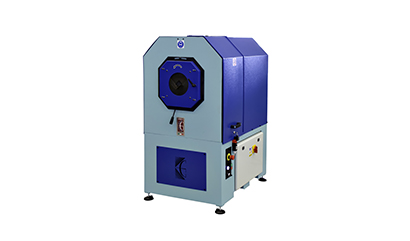

NOK 150

Notching and belt grinding machine

G = 15-60 degrees

G = 15-60 degrees  D = 20-150 mm (6" max)

D = 20-150 mm (6" max)

ROTOR

Orbital brush deburring machine

D = 10-210 mm (8" max)

D = 10-210 mm (8" max)  L = 10-150 mm

L = 10-150 mm

Assistance needed?

Get in touch with our Customer Service

Garboli put at disposal his skilled personnel to support you with technical advices,assistance and information about products and services.

Websolute

Websolute